Industrial manufacturers make materials like aluminum and glass for everything from beverage containers to aircraft parts. They’re also responsible for 17% of global carbon dioxide emissions, according to recent research published in PNAS Nexus.

That’s a problem. Countries are struggling to cut CO2 emissions as the climate crisis worsens. And switching these major manufacturers to cleaner sources of energy, like wind and solar, would help significantly.

But when the sun isn’t shining or wind isn’t blowing, these manufacturers need to rely on stored energy. Batteries are one option, but some scientists think an ancient technology, firebricks, is a cheaper and easier solution.

Firebricks are cheap and effective

If you have a brick fireplace, you might notice the bricks stay warm for a while after the fire goes out.

People have used bricks to help keep kilns and ovens hot since the Bronze Age. Even modern industrial manufacturers use firebricks in daily operations.

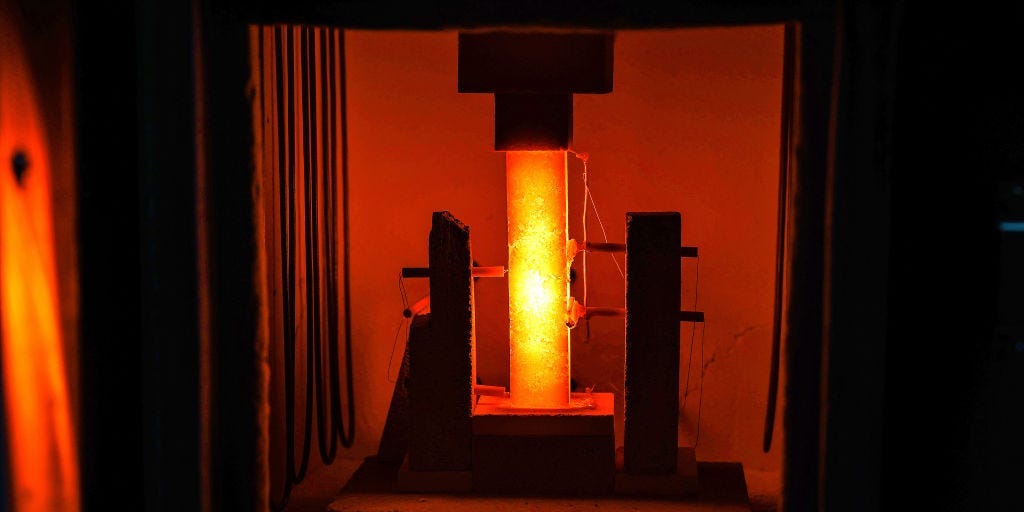

They stack the bricks in tall rows, heat them up to extremely high temperatures, and then blow air through channels to harness the heat for melting glass or metal, for example.

Heating up the bricks causes carbon emissions since manufacturers typically burn fossil fuels to do it.

However, a few new companies think they’ve figured out how to use electricity from the grid to heat up the bricks instead.

Electrified Thermal Solutions and other companies make firebricks that conduct electricity.

“A normal firebrick is an insulator like rubber. Electricity just doesn’t go through it,” MIT professor Charles Forsberg, an advisor to the company, said.

However, when you add compounds like chromia and nickel oxide the firebrick becomes an electrical conductor.

Forsberg said these conductive bricks function similarly to an electric oven, except the firebrick can handle heat that would melt your oven’s wires.

“It’s a way to heat firebricks to a blazingly hot temperature,” he said. It can reach 3,270 degrees Fahrenheit, more than hot enough to melt steel, The Boston Globe reported.

Instead of storing the electricity like a battery, the bricks would store heat. So, a steel mill, for example, could take electricity from the grid. The high electrical current would heat up the oxides inside the firebricks, and the bricks would retain the heat, which the manufacturer could then use to melt metal.

Of course, there’s still the issue that electricity from the grid often comes from fossil fuels. But eventually, as more renewable energy feeds the grid, this could help major manufacturers drastically reduce carbon emissions, and also save a lot of money.

Mark Jacobson, a professor at Stanford University, estimated in the PNAS Nexus study that transitioning 149 countries entirely to renewable energy by 2050 would cost about $59 trillion. He and his colleagues used computer models to examine two options: one where industries used firebricks and one where they relied on technologies like electric furnaces and boilers and stored energy in batteries.

Implementing firebricks saved over $1.2 trillion dollars worldwide, he told Business Insider.

The savings partially come from the bricks’ cheap cost, which are about a tenth of the price of traditional storage batteries, Jacobson said. “When we use firebricks, we reduce the cost of batteries because we need fewer batteries,” he said.

Making small changes for big emissions savings

Forsberg said early adopters of conductive firebricks might still use natural gas or oil if they run out of stored heat.

“Someday in the future, it may all be electric,” he said, “but my guess is in the near term, most of the people who need high-temperature heat are going to buy a cheap gas burner.”

It’s also going to take a while to get these new firebricks installed. Jacobson said the first adopters might be companies that need to replace their equipment or newcomers starting from scratch. Once they do, though, “I think they’ll find that it’s actually much more beneficial,” he said.

Electrified Thermal Solutions is working on one of its first industrial applications, replacing gas boilers in a Kentucky chemical plant.

Another company, Rondo, has installed its technology in a biofuel company in California. Rondo said its system reduces CO2 emissions and lowers the cost of energy because it requires less electricity than hydrogen fuel.

Having a few successful example projects might help change some minds in other industries, Jacobson said.

Forsberg said one of the biggest benefits of the newer firebrick technology is that it updates processes many industries have in place. “The goal is minimum change,” he said. “If you want to cause a revolution in technology, don’t change anything you don’t have to change.”

Read the full article here